Hi lovely makers! I am back with a hopefully interesting post about how sewing machines actually work. I have already written a couple of posts regarding the history of the sewing machine and who and when was invented, but I also wanted to go into the more technical stuff on a different post.

Now, how machines do really work?

The inner workings of a sewing machine

Whether modern or old, computerised or mechanical, all sewing machines work in a (more or less) similar way since its invention in the late 1700s.

The two mechanisms involved are the Double-Thread Stitching and the perfect Synchronization of the Stitching and Fabric Motion, sounds fancy, right? Let's take a look at both.

1. Double-Thread Stitching

As you can see in the slow-motion video below, the needle passes the thread through the fabric, so that it can make a knot with a second thread coming from the bobbin before being pulled back up again. The first time I looked at this video I was mesmerized!

Continue reading for a more detailed explanation...

- The needle tied to the spool thread, or upper thread, pierces both the fabric and the needle plate below it.

- The needle then rises a bit so that the thread, pushed against the underside of the needle plate, folds into a loop.

- The loop is caught by a rotating hook (the bobbin case) which widens it and makes it circle the case and the small bobbin within. This bobbin supplies the second thread, also called lower thread.

- When the hook's rotation is complete, the lower thread is caught in the upper thread's loop and together they make a knot.

- Finally, the needle pulls the upper thread back up, tightening the knot against the fabric. The stitch is done and the cycle can start again.

Now for the second step.

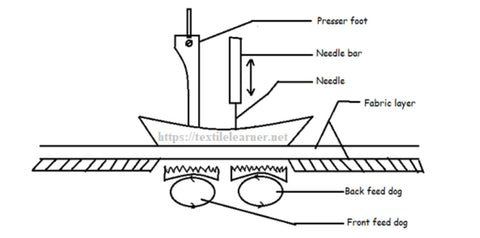

The feed-dog and presser foot are the heroes here. They both help moving the fabric through the machine at a steady speed, ensuring that the stitches are of equal length.

The feed-dog works by moving upwards and forwards at the same time, which happens through two interlinked mechanisms driven off the main shaft.

At the same time, a second crank mechanism moves the feed-dog up and down. When these two movements are synchronized, the feed-dog works a bit like a shoe on the end of an upside-down leg.

Normally, a shoe on your leg moves down and backward, then lifts up and repeats the same movement, pushing back against the ground so your body moves forward. But a feed dog (with the shoe in effect pointing upward) moves upward and forward, "walking" the material through the machine one step (or stitch!) at a time.

I found another great explanation from Hobby Couture plus image of how this process works from the very beginning:

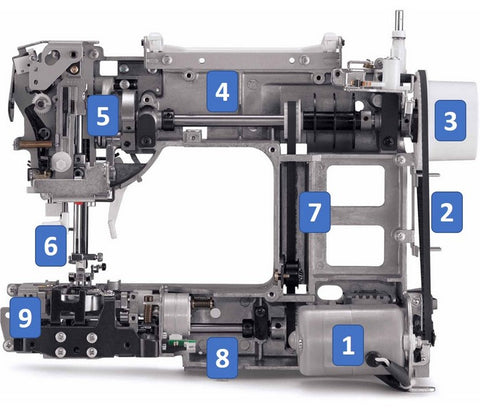

It all starts with the machine's power source, which nowadays is an electric motor [1] operated by a pedal.

The motor's rotation drives a belt [2] stretched between two disks. To put it simply, it's like a bike chain connected on one side to the disc that turns when you pedal (= the motor) and on the other to the disc connected to the wheel (= the hand wheel [3]).

This hand wheel [3] is connected to the upper drive shaft [4]. A drive shaft is a cylinder of any length that rotates on itself, in order to transfer movement from one area of a machine to another. In the case of sewing machines, the upper shaft transmits movement to two components:

- A crank [5] that raises and lowers the vertical axis connected to the needle [6].

- A second belt [7] connected to a second drive shaft [8]. These two parts are parallel to the first and mimic them, which enables the mechanism in the bottom of the sewing machine to be perfectly synchronised with the top.

The bottom mechanism [9] is made of the bobbin case and its lower thread which forms the knot with the upper thread, and the feed dogs that move the fabric between stitches.

I hope you found this post interesting. Have you ever seen a sewing machine open like this in real life?

Thank you for reading!

Ana

xxx

Reference links:

Explain Stuff

Textile Learner

Hobby Couture